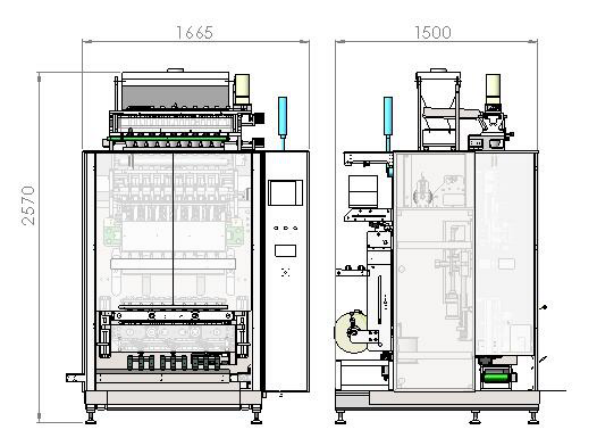

Dxdk750 product appearance and sample bag

It can be used in medicine, food, cosmetics and other industries. It can automatically fill and pack tablets, capsules, regular shaped tablets, granules, powders, liquids and other different forms of materials.

Brief introduction of dxdk750 multi row back sealing packaging machine

Dxdk750 multi column back sealing automatic packaging machine is a high-quality and high-performance automatic packaging machine developed by our company, which has a series of automatic functions such as material feeding, metering, bag making, filling, sealing, printing date and finished product output. The machine adopts high precision film transportation system, PLC program control, advanced touch human-machine interface, photoelectric automatic tracking, PID digital constant temperature control system, etc. the operation of the machine is simple and perfect. It is the first choice equipment for food and drug packaging industry to improve production efficiency, reduce labor intensity and improve packaging grade.

This equipment is an automatic packaging machine, which is used for cold rolling pure aluminum composite packaging, multi-layer composite film, plastic film and other bag packaging. The supporting multi-channel material filling device can continuously fill the packaging bag with packaging materials, and simultaneously cut out single or multiple packages.

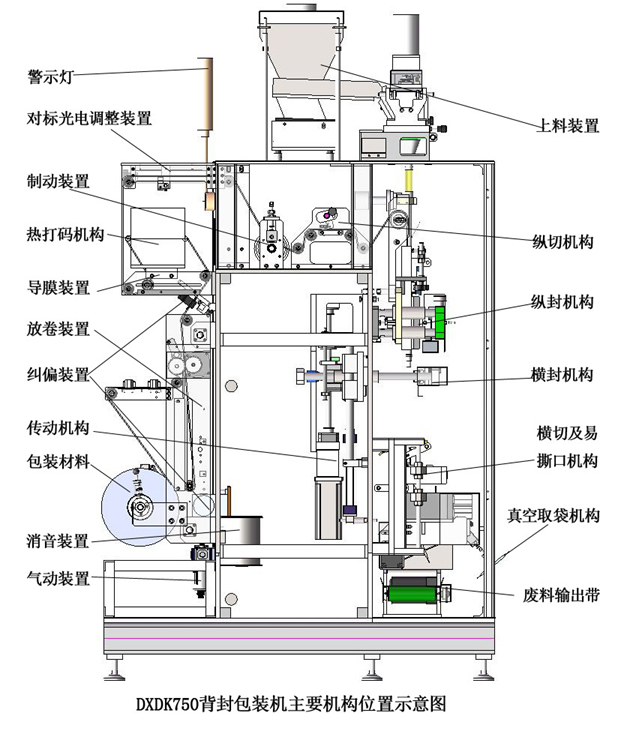

Dxdk750 main mechanism location diagram

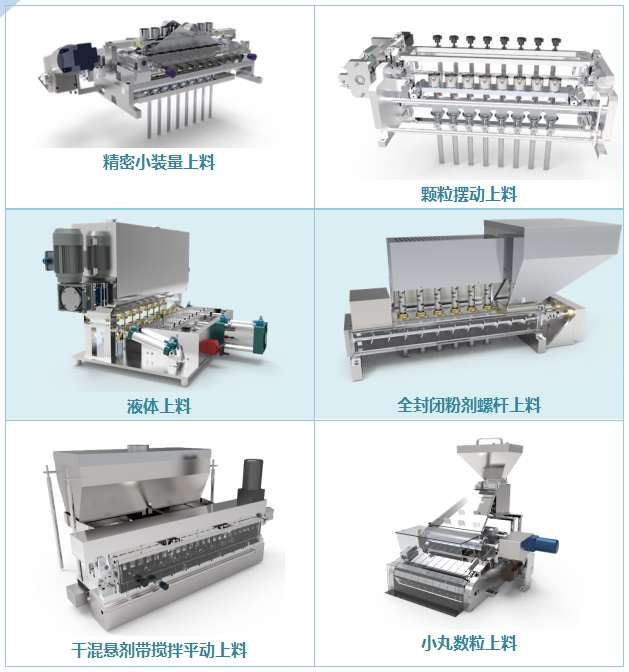

Main feeding methods of dxdk750

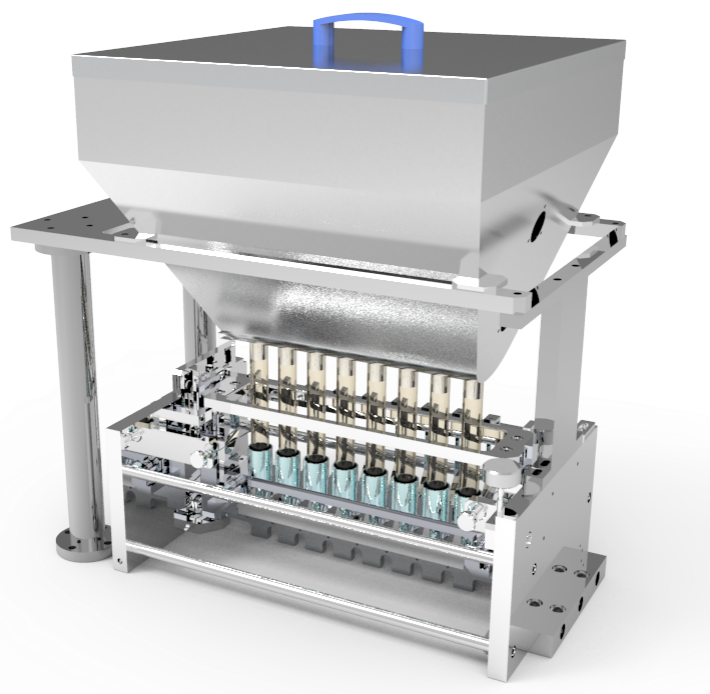

The filling time is realized by adjusting the man-machine interface to control the cylinder, and the filling time starts at the moment after the transverse seal is closed. Metering adjustment method: first, open the feeding switch, first adjust the position relationship between the mobile material pipe and the metering bucket, when the metering bucket is completely closed, the mobile material pipe can be moved to the metering bucket to start blanking, and the mobile material pipe can be moved to the metering plate, and the metering bucket can be opened. If the position is not right, the position of cylinder 1 and cylinder 2 should be adjusted accordingly, and the blanking time can only be adjusted after the position of the swinging material pipe and the metering bucket is adjusted. Adjust the blanking time. The correct blanking time is: when the transverse seal is horizontally sealed, the metering bucket is about to open. When the position is not correct, the opening time of cylinder 2 needs to be adjusted. Only when the position is correct can the feeding be started.

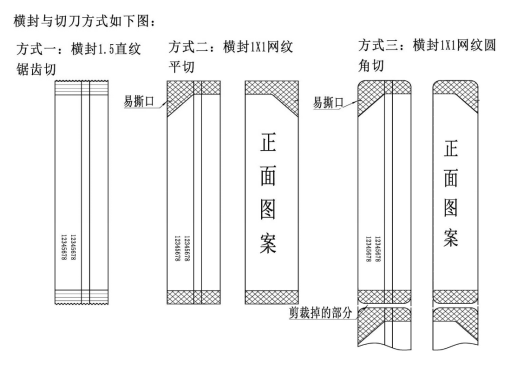

Main crosscutting modes of dxdk750

Our company provides three kinds of cross cutting methods, flat cutting, serration cutting and die cutting.

设备型号 | DXDK750 |

包装范围

| 广泛的应用于食品,医药和化工产品中的松散,无粘性的颗粒状物料的自动包装。如(药品)冲剂,速溶咖啡,味精,白糖,干燥剂等。也可用于粉剂,液体和粘稠液体的包装。 |

包装功能 | 具有完成自动送料、计量、制袋、充填、封口、打印日期及成品输出等一系列自动功能,也可根据用户的要求实现自动对正色标的功能。该机的上料部分改变了以往比较单一的下料方式,采取了依据不同的药品而采用不同的上料机,上料类型丰富,满足不同用户需求。 |

包装材料 | 尼龙膜/聚酯膜复合,聚酯膜/聚酯复合膜,尼龙膜/纯铝箔/聚酯膜复合,聚酯膜/纯铝箔复合,聚酯膜和其他可提供热封合功能的材料复合.(包装材料不能是易燃,易爆,易腐等列入危险化学品或物质的材料) 包材******宽度:750mm; 包材******外径:φ300mm; 包材芯径:φ75mm; 包材厚度:0.05-0.1mm |

电源规格 | 380V 50Hz |

总用电功率(kw) | 8.5kw(根据列数不同略有不同) |

压缩空气压强(Mpa) | 0.6 Mpa |

压缩空气耗量(m3/min) | 1.8立方米/分 |

噪声(dBA) | 78dB(A) |

外形尺寸(L*W*H) | 1650*1500*2850mm(高度依据客户要求略有不同) |

包装物料 | 颗粒冲剂 液体 粉剂 |

纵向列数 | 4-12列 |

包装容量 | 2-200ml 计量精度:±5% |

制袋能力 | 袋宽20mm≤W≤70mm 袋长:50mm≤L≤190mm |

包材宽度 | 750mm |

生产日期批号 | 配色带打码或钢打码,激光打码 |

切刀方式 | 平刀切、锯齿切,圆角切 |

包材 | 复合包装材料(BOPP/PE等) |

横切断频率(次/钟) | 20-40次/分钟,依据使用要求可进行无级(设定)调整。 |

重量(kg) | 2400kg |

生产过程自动控制能力 | 物料充填、包材张力、封合温度、裁切速度、切线控制、无级调速 |

已通过鉴定级别 | 市产品质量监督检验所 |

对用户承诺 | 实行三包:一年保修,常年维修,长期供应配件,省内24小时,外省48小时内现场服务。 |

工作原理: | 包装材料由位于机体后侧的放卷机构导出,经放卷辊后进入打印批号(可根据可选择)、纵切、热封成型并在此处完成了对物料充填及封合过程,然后通横封、横切最后形成成品输出。 |

基本配置及结构 | 该机主要由机体、充填系统、传动系统、薄膜放卷、封合、打字(可选配热打码机)、纵切、横切、输送机(选配)、气动系统、电控系统等部分组成。 |

机体: | 机体是整机的基础,DXDF750多列背封包装机的机体采用了钢板框架结构焊接结构,其机体为结构钢焊结而成,烤漆架体(外部为白钢板),使机体有足够的刚度以保证机器安全运转,机体左侧和后面均有可打开,便于安装、检查和设备的维修,机体内为传动系统,该机的电控箱在机体右侧,方便操作。机体的接地部分为六个可调节的地脚。 |

充填系统: | 由于该机自身特点的要求,因此对充填系统有着特殊的要求根据不同药品的形状和特点相应的改变了供料的方式以保证充填的合格率。其充填滑效果优良。 |

List of main electrical materials of dxdk750 multi column back sealing packaging machine (take 10 columns as an example)

物 资 名 称 | 规 格 型 号 | 单位 | 数量 | 厂家 |

可编程控制器 | FX3U-48MT | 1 | 三菱 | |

空气开关 | 1P6A | 1 | 天水 | |

空气开关 | 1P10A | 3 | 天水 | |

直流电源 | S50-2A | 1 | 明纬 | |

中间继电器 | RJ2S-CL-DC24V | 4 | 和泉 | |

固态继电器 | E1542-32K | 10 | 百特 | |

固态继电器 | E4042-32K | 2 | 百特 | |

伺服驱动器 | ASD-B2-1521-B | 1 | 台达 | |

主伺服电机 | ECMA-E11315SS | 1 | 台达 | |

温控模块 | SAT100-000011 | 3 | 汇邦 | |

加热扁带 | 22*750 | 4 | 自制 | |

加热管 | 10*200 | 10 | 自制 | |

热电偶 | 12 | 自制 | ||

人机界面 | MT6103IP | 1 | 威纶 | |

接近开关 | PRE12-4DN | 3 | 奥托尼斯 | |

接近开关 | PSNT17-5DO | 1 | 奥托尼斯 | |

对标开关 | Z3N-T22 | 1 | JULONG |

在线咨询

QQ咨询

微信二维码